Description

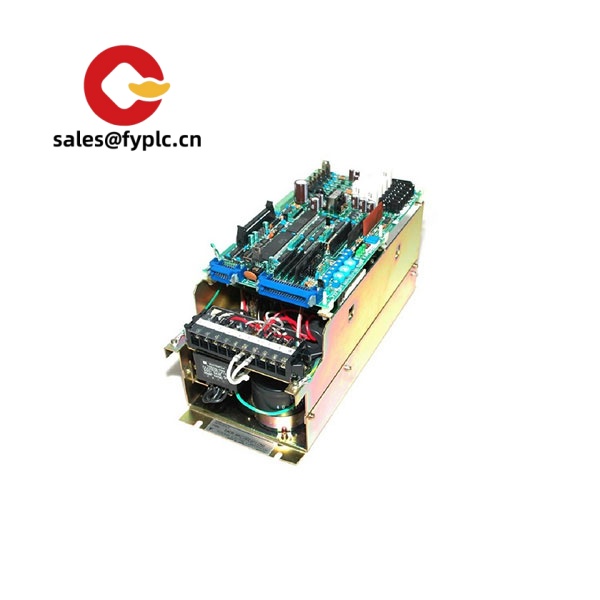

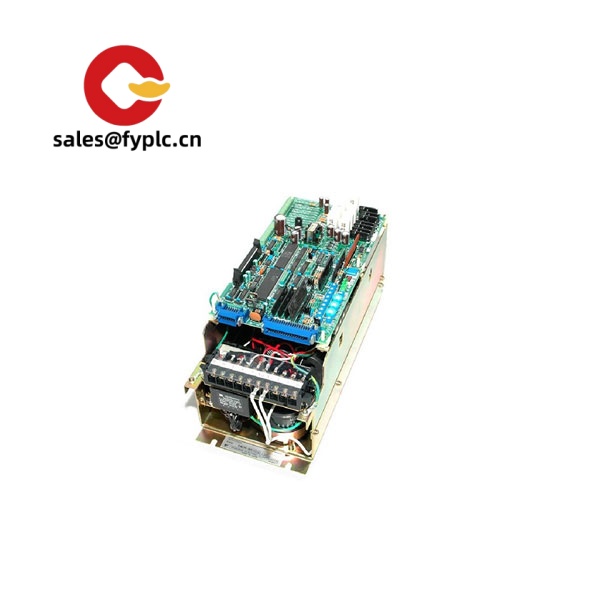

Yaskawa CACR-SR15BB1BM – AC Servopack Drive for Legacy Motion Systems and Reliable Retrofits

The Yaskawa CACR-SR15BB1BM is part of Yaskawa’s classic CACR-SR Servopack family, widely used on legacy equipment where stable analog control and pulse-positioning are still required. From my experience, this model is typically paired with Yaskawa 200 V-class AC servo motors and keeps older packaging lines, printing machines, and general automation cells running without forcing a full control platform overhaul. You might notice that it’s built for straightforward integration—analog speed/torque command, pulse train position input, and standard encoder feedback—so it tends to drop into existing panels with minimal rework.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: In-stock items ship in about 1 week; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Analog and pulse command modes: Accepts 0–10 V analog (speed/torque) and pulse-train inputs (CW/CCW or A/B), which makes it friendly for PLCs and older CNCs.

- Incremental encoder feedback: Designed for standard Yaskawa AC servo motors with TTL encoder feedback; tuning is handled via front-panel potentiometers and DIP switches.

- Stable control loop: The CACR-SR platform is known for dependable speed and position stability in many cases, even on machines with long duty cycles.

- Simple panel integration: Panel/cabinet mount with straightforward I/O terminals; typically no fieldbus required.

- Designed for 200 V-class systems: Usually applied on 200–230 VAC servo setups common in Asia, EU, and North America.

- Serviceable for long life: Easy access to terminals and trimmers; routine cleaning and capacitor health checks extend operating life.

Technical Specifications

| Brand / Model | Yaskawa CACR-SR15BB1BM (CACR-SR series Servopack) |

| HS Code | 850440 (Static converters / servo drives) |

| Power Requirements | 200–230 VAC, 50/60 Hz (typically three-phase for ≥1 kW applications) |

| Operating Temperature | 0 to 55°C, non-condensing; derating may apply near upper limit |

| Signal Input/Output Types | Command: 0–10 V analog (speed/torque), pulse train (CW/CCW or A/B). Feedback: Incremental encoder (TTL A/B/Z). Digital I/O: Servo ON, alarm, ready, limit signals (typical). |

| Communication Interfaces | No fieldbus; local setup via front-panel trimmers/DIP switches |

| Installation Method | Panel/cabinet mount, vertical orientation, proper grounding and shielding recommended |

| Dimensions & Weight | Compact panel-mount chassis; exact size/weight vary by production batch—verify on nameplate for your unit |

| Typical Motor Pairing | Yaskawa 200 V-class AC servomotors (U/US series with incremental encoder) |

Application Fields

This model shows up a lot in legacy systems where reliability and like-for-like replacement matter more than adding a modern fieldbus. Typical use cases include:

- Packaging machinery (form-fill-seal, cartoners, indexing conveyors)

- Printing and labeling lines needing precise speed/registration control

- Pick-and-place, light assembly fixtures, and feeders

- Winders/unwinders in film, foil, or paper handling

- General-purpose retrofits where the original controller outputs analog or pulse commands

One thing I appreciate is how it avoids forcing a controls redesign. A packaging OEM told us they swapped a failed older Servopack for this CACR-SR unit and were able to keep the original PLC logic, wiring scheme, and encoder without chasing new part numbers.

Compatible Components & Accessories

- Yaskawa AC servomotors (200 V-class): US-/U-series motors with incremental encoders pair well with CACR-SR drives.

- Encoder and power cables: Use shielded motor power and encoder cables to minimize noise; keep motor and feedback routes separated.

- Regenerative resistor (if required): External braking resistor may be used for rapid deceleration or high-inertia loads.

- EMC/line accessories: Line reactor and EMC filter are recommended in many cases to reduce harmonics and improve immunity.

Advantages & Value

- Drop-in compatibility: Keeps legacy analog/pulse motion architectures intact and reduces commissioning risk.

- Reliable operation: The CACR-SR line has a reputation for durable performance in 24/7 environments.

- Cost-effective retrofit path: Avoids replacing motors, PLC I/O cards, and encoder wiring—saves time and budget.

- Straightforward support: Setup is practical—no complex software; adjustments by potentiometer and DIP settings.

Installation & Maintenance

- Cabinet environment: Mount vertically in a ventilated cabinet. Provide clearance for airflow; avoid dust/oil mist exposure where possible.

- Power and grounding: Use a dedicated 200–230 VAC feed with proper protective devices. Ground the drive and motor per Yaskawa guidelines; bond cabinet doors to eliminate noise pickup.

- Wiring practices: Separate motor power and encoder cables. Use shielded cables and terminate shields at the drive end. Keep pulse/analog command lines short.

- Tuning and setup: Set command mode (analog/pulse) via DIP switches. Adjust speed/position loop gains using the trimmers; verify with a low-inertia test before full-load runs.

- Routine maintenance: Inspect fans/filters (if fitted), clean dust, check terminal tightness, and evaluate electrolytic capacitors on older units. Firmware is not typically field-updated on this series.

- Safety: Discharge time applies after power-off; confirm DC bus is safe before servicing. Use a braking resistor if application demands frequent fast stops.

Quality & Certifications

- Manufacturer quality: Yaskawa industrial-grade Servopack

- Certifications: Typically CE and UL for industrial control (model-year dependent); documentation available on request

- Warranty: 365 days (repair/replace policy subject to evaluation)

If you’re replacing an existing CACR-SR or migrating from a similar analog/pulse servo, this CACR-SR15BB1BM seems to be one of the safer choices to maintain machine behavior with minimal engineering time. Share a photo of your nameplate and motor model, and we can validate compatibility before you place the order.

Reviews

There are no reviews yet.