Description

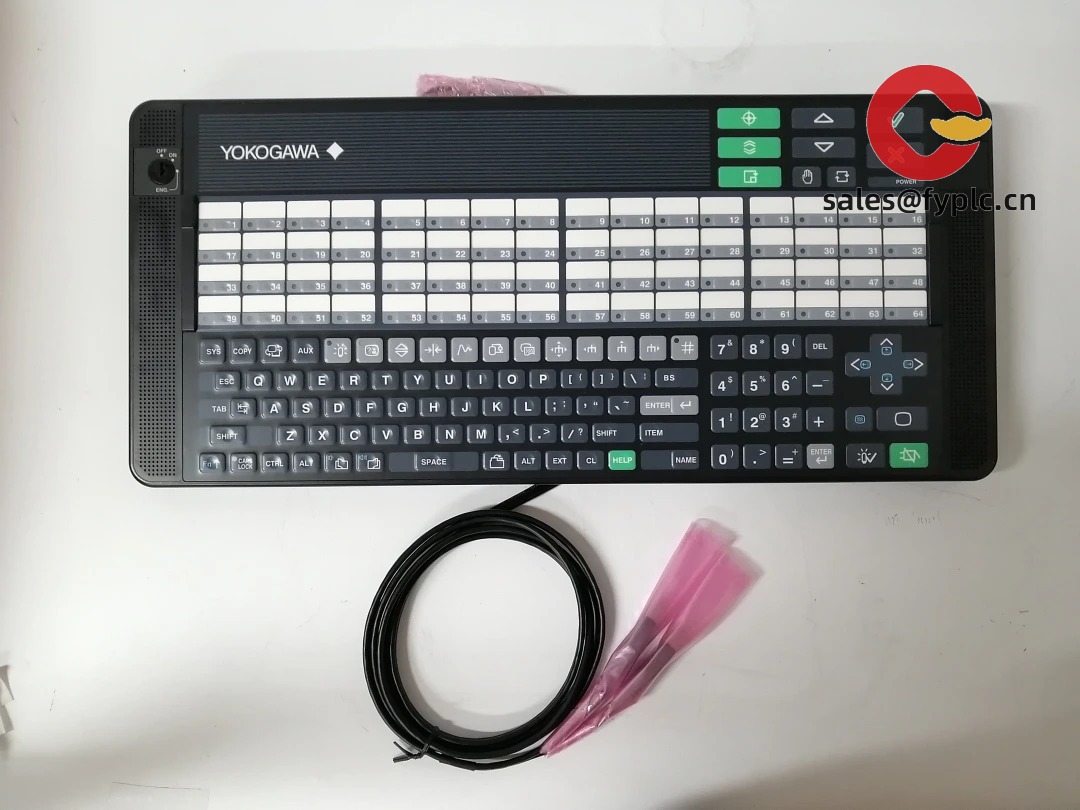

YOKOGAWA AIP830-111 – Analog Input Module for Stable, Scalable Process I/O

The YOKOGAWA AIP830-111 is an analog input module commonly used in CENTUM-class distributed control systems where reliable 4–20 mA and DC voltage measurements matter. From my experience, this series is a practical fit for plant upgrades and spare-part programs because it preserves existing wiring practices while bringing consistent signal conditioning and straightforward commissioning. You might notice that it drops into standard Yokogawa I/O bases, which keeps panel work tidy and typically reduces switchover time.

Company’s Order Placement Process and Guarantees

- Warranty period: 365 days

- Delivery time: 1 week for in-stock items; no more than one month at the latest

- Payment: 50% advance payment; full payment prior to delivery

- Express options: FedEx, UPS, DHL

Key Features

- Multi‑channel analog input – Designed for common process signals such as 4–20 mA and DC voltage, suitable for flow, pressure, level, and temperature transmitters.

- Stable signal conditioning – Filtering and conversion tuned for process control; helps suppress noise typically seen in long field runs.

- Backplane integration – Interfaces through the Yokogawa I/O backplane, simplifying cabling and controller communication.

- Single‑slot footprint – Saves cabinet space and usually avoids rework during brownfield replacements.

- Field‑wiring friendly – Works with terminal bases/blocks used across the Yokogawa I/O family, easing channel mapping and loop checks.

- Lifecycle fit – Often selected as a like‑for‑like spare to keep legacy nodes healthy while planning larger migrations.

Technical Specifications

| Brand / Model | YOKOGAWA AIP830-111 |

| HS Code | 8538.90 (Parts suitable for use with the apparatus of heading 8537) |

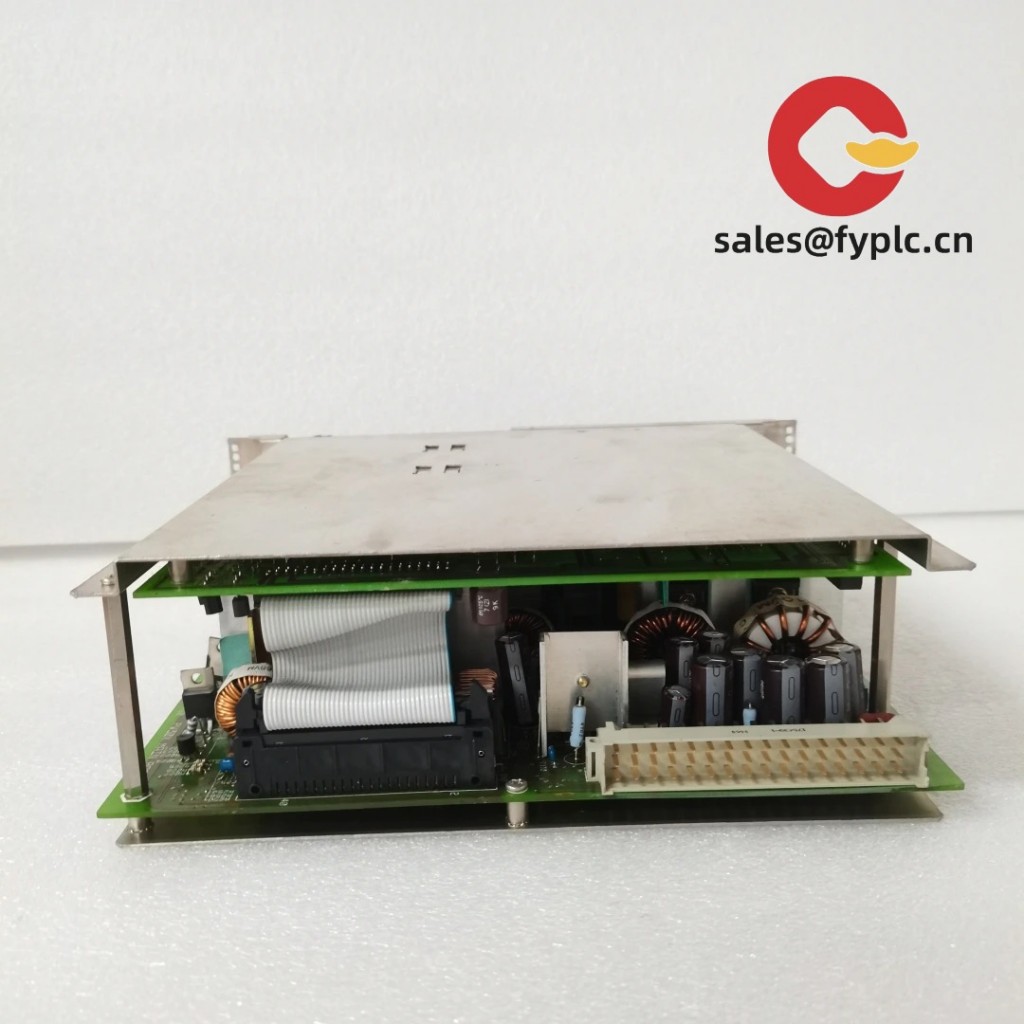

| Power Requirements | Backplane powered via Yokogawa I/O node (no separate external supply required for the module) |

| Dimensions & Weight | Single‑slot I/O card form factor; lightweight module suitable for standard Yokogawa I/O racks |

| Operating Temperature | Typically 0 to 55°C (consult system manual for exact limits) |

| Signal Input/Output Types | Analog inputs; commonly 4–20 mA and DC voltage ranges used in process control |

| Communication Interfaces | Module communicates to the controller through the Yokogawa I/O backplane/bus |

| Installation Method | Plug‑in card for system baseplate/rack; field wiring via associated terminal base or terminal block |

Application Fields

Plants running continuous or batch processes typically deploy the AIP830‑series in:

- Chemical and petrochemical units capturing 4–20 mA signals from pressure and flow transmitters

- Oil & gas upstream and midstream skids bringing multiple analog loops into a central DCS node

- Power and utilities monitoring boiler and balance‑of‑plant instrumentation

- Water and wastewater systems integrating reservoir level, dosing, and turbidity signals

- Pharmaceutical and food processes where stable analog inputs improve batch repeatability

Advantages & Value

- Reliability – Proven analog input performance; in many cases, these modules run for years without attention.

- Compatibility – Fits the Yokogawa ecosystem; keeps your I/O mapping and control strategy intact during maintenance.

- Cost Control – Straightforward swap minimizes downtime; no surprise panel redesigns.

- Technical Support – Clear channel diagnostics and established commissioning steps make loop checks faster.

One thing I appreciate is how easily technicians can perform loop-by-loop validation. A maintenance lead recently told me, “We swapped the AIP card during a window and were trending the signals again within the hour.”

Installation & Maintenance

- Cabinet & environment – Mount in a clean, ventilated control cabinet; maintain ambient within the stated operating range.

- Wiring – Use shielded twisted-pair for analog loops; land shields per plant grounding practice to avoid ground loops.

- Terminal base – Verify the correct terminal block/baseplate for the AIP830‑series and check channel assignment before energizing.

- Safety – De‑energize loops where required; tag wires; confirm polarity on current inputs to prevent misreads.

- Commissioning – Perform loop checks with a calibrated source; confirm scaling and range in the controller database.

- Upkeep – Periodic inspection for loose terminations, cleaning of dust from card edges, and occasional firmware/config backups at the controller level.

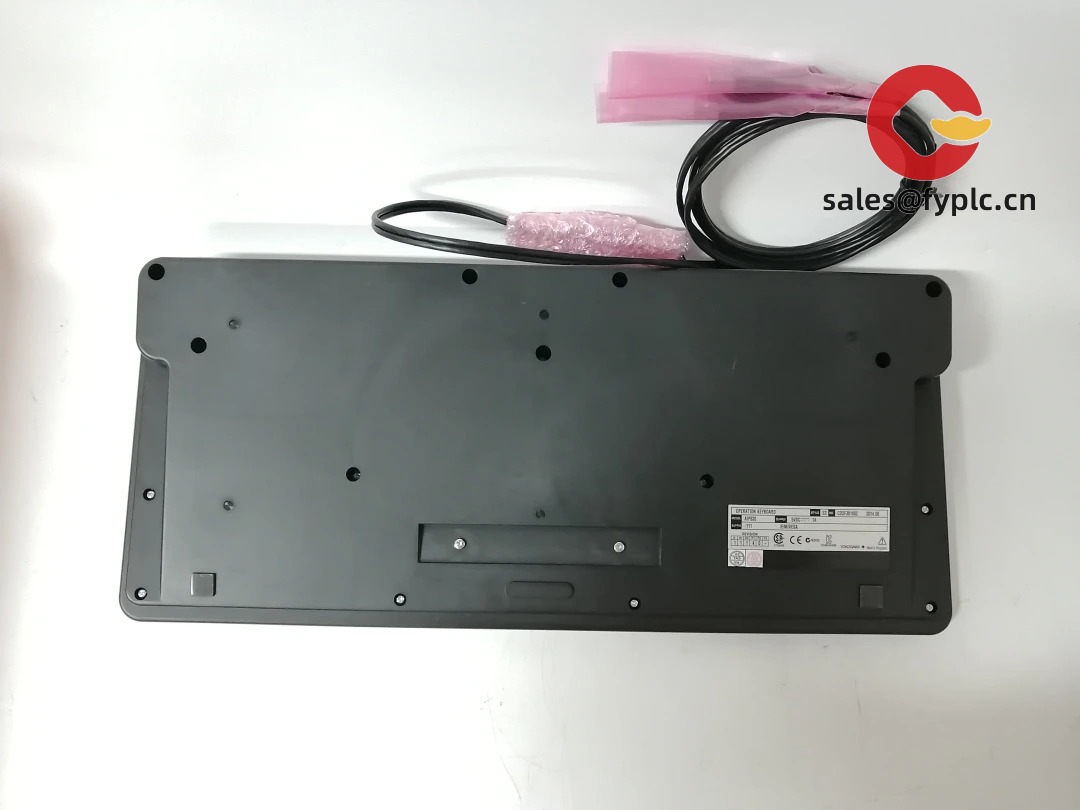

Quality & Certifications

- Manufacturer operates under ISO 9001 quality systems

- CE compliance and RoHS alignment are typical for Yokogawa I/O modules

- UL/CSA recognition may apply depending on the system rack and region

- Supplied with a 365‑day warranty

If you’re standardizing spares or planning a node refresh, the YOKOGAWA AIP830-111 seems to be a safe, low‑risk piece to keep your analog measurements stable without disrupting the rest of the DCS. If you’d like, share your channel count and signal ranges, and I can suggest the matching terminal base and a wiring checklist tailored to your panel.

Reviews

There are no reviews yet.