Description

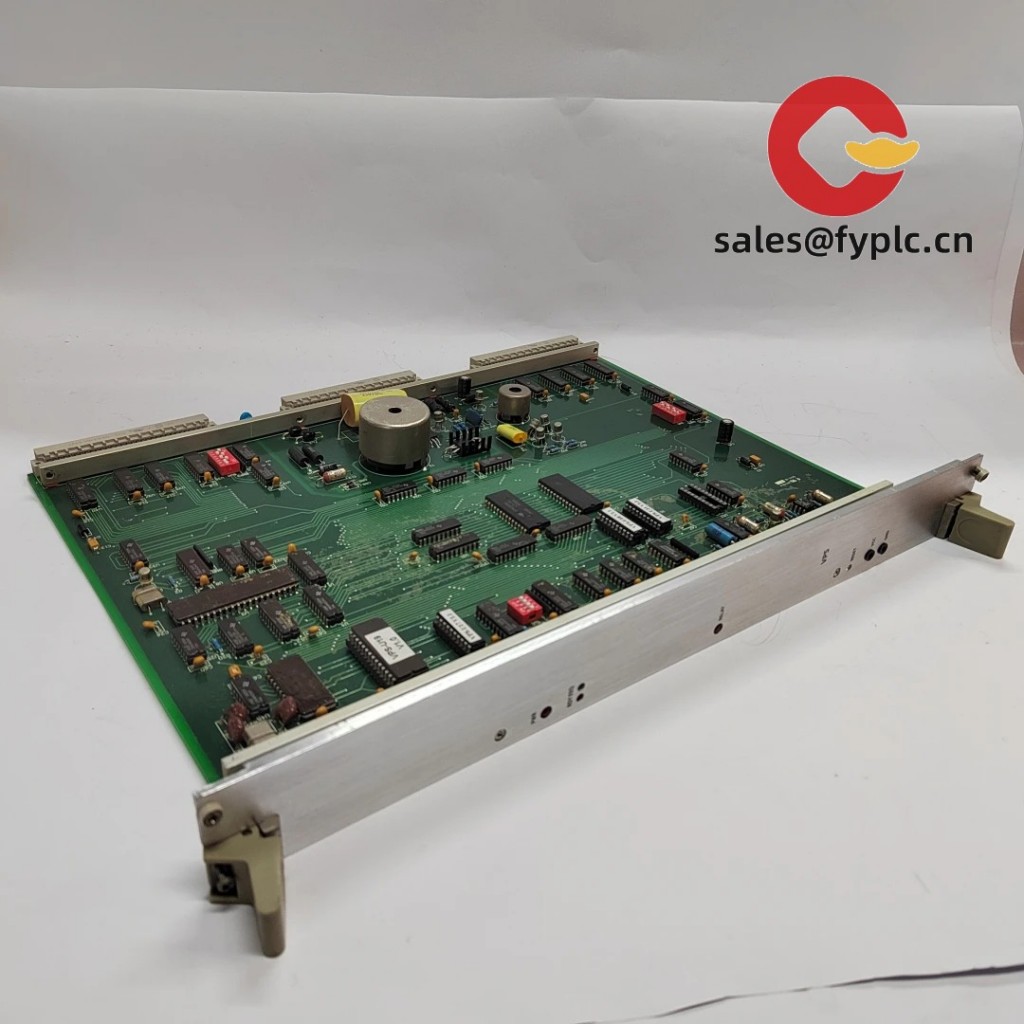

YOKOGAWA ALR121-S00 – Alarm/Relay Output Interface for Plant Annunciation and Discrete Signaling

The YOKOGAWA ALR121-S00 is typically used as an alarm/relay output interface within CENTUM VP/CS series or related Yokogawa I/O nodes. From my experience, it’s the kind of module you deploy when you need reliable, isolated contact outputs for horns, beacons, panel lamps, or interlocks tied to process alarms. It seems to be a practical choice for brownfield upgrades too—drop-in to the system base, wire to the terminal block, and you’re back online with minimal downtime.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than 1 month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Discrete alarm/contact outputs – Typically used to drive beacons, buzzers, annunciator lamps, or hardwired interlocks.

- Backplane-powered integration – Plugs into the Yokogawa system base; no external power supply in most cases.

- Channel isolation and protection – Designed to provide stable switching with reduced cross-talk, which helps in noisy industrial cabinets.

- Diagnostics and status indication – You might notice clear status LEDs and simple diagnostics that speed up I/O checkout during commissioning.

- Maintenance-friendly form factor – Field wiring stays on the terminal block; the module can typically be swapped quickly.

- System compatibility – Works within Yokogawa DCS/PLC I/O racks, keeping engineering and spares consistent across units.

Technical Specifications

| Brand / Model | YOKOGAWA ALR121-S00 |

| HS Code | 853890 (Parts for industrial control apparatus) |

| Power Requirements | Powered via system backplane; no separate external supply typically required |

| Operating Temperature | 0 to 50 °C (typical for Yokogawa system I/O) |

| Signal I/O Type | Discrete alarm outputs (contact/relay-style), for horn, lamp, and interlock annunciation |

| Communication Interface | System backplane bus (no external comms port on the front) |

| Installation Method | Plug-in module for Yokogawa I/O base/rack; field wiring via terminal block |

Application Fields

You’ll typically see the ALR121-S00 wherever process alarms need a hardwired output. It’s useful in:

- Refinery and petrochemical units for horn/beacon annunciation on trip conditions

- Power plants and boiler houses for local panel lamps and alarm panels

- Pharmaceutical and food plants where discrete interlocks are still required for compliance

- Water/wastewater stations for pump fault alarms and MCC interfacing

- OEM skids needing a reliable DCS-connected contact output interface

A maintenance lead at a gas processing site told us they swapped an ALR121-S00 into an existing rack in under 10 minutes—no wiring changes, just reseat, verify status, and run an alarm test. That seems to be the norm when the system base is already standardized on Yokogawa.

Advantages & Value

- Reliability in harsh panels – Good tolerance to electrical noise and steady switching performance, which reduces nuisance trips.

- Compatibility with Yokogawa architectures – Keeps your engineering database, spares, and maintenance tools consistent.

- Lower lifecycle cost – Quick replacement and simple diagnostics typically cut mean time to repair.

- Procurement-friendly – Stable part coding and long availability windows help planning and inventory control.

- Technical support – We provide pre-checks before shipment and can share typical wiring/application notes on request.

Installation & Maintenance

- Cabinet & environment – Install in a clean, ventilated control cabinet; typical operation 0–50 °C, non‑condensing humidity.

- Mounting – Plug into the designated Yokogawa I/O base/rack. Keep spacing per the system manual to maintain airflow.

- Wiring – Use properly rated conductors. Keep alarm output wiring separate from high-noise power lines; ground shields at one end.

- Safety – Isolate power and follow LOTO procedures before inserting or removing the module.

- Routine checks – Periodic functional tests of the alarm outputs (lamp/horn tests) and visual inspection of terminal tightness are recommended.

- Firmware/config – If applicable in your system revision, keep controller/engineering station software aligned with the plant’s validated version.

Quality & Certifications

- Manufacturer quality system: typically ISO 9001

- Compliance: CE marking; RoHS conformity in many cases; UL/cUL recognition may apply depending on system variant

- Warranty: 365 days (bench test prior to shipment can be arranged)

Notes on Compatibility

For best results, confirm the exact system base/rack and controller revision where the ALR121-S00 will be installed. If you’re coordinating with mixed I/O types, we can help review the slot plan and terminal assignments so commissioning goes smoothly.

Reviews

There are no reviews yet.