Description

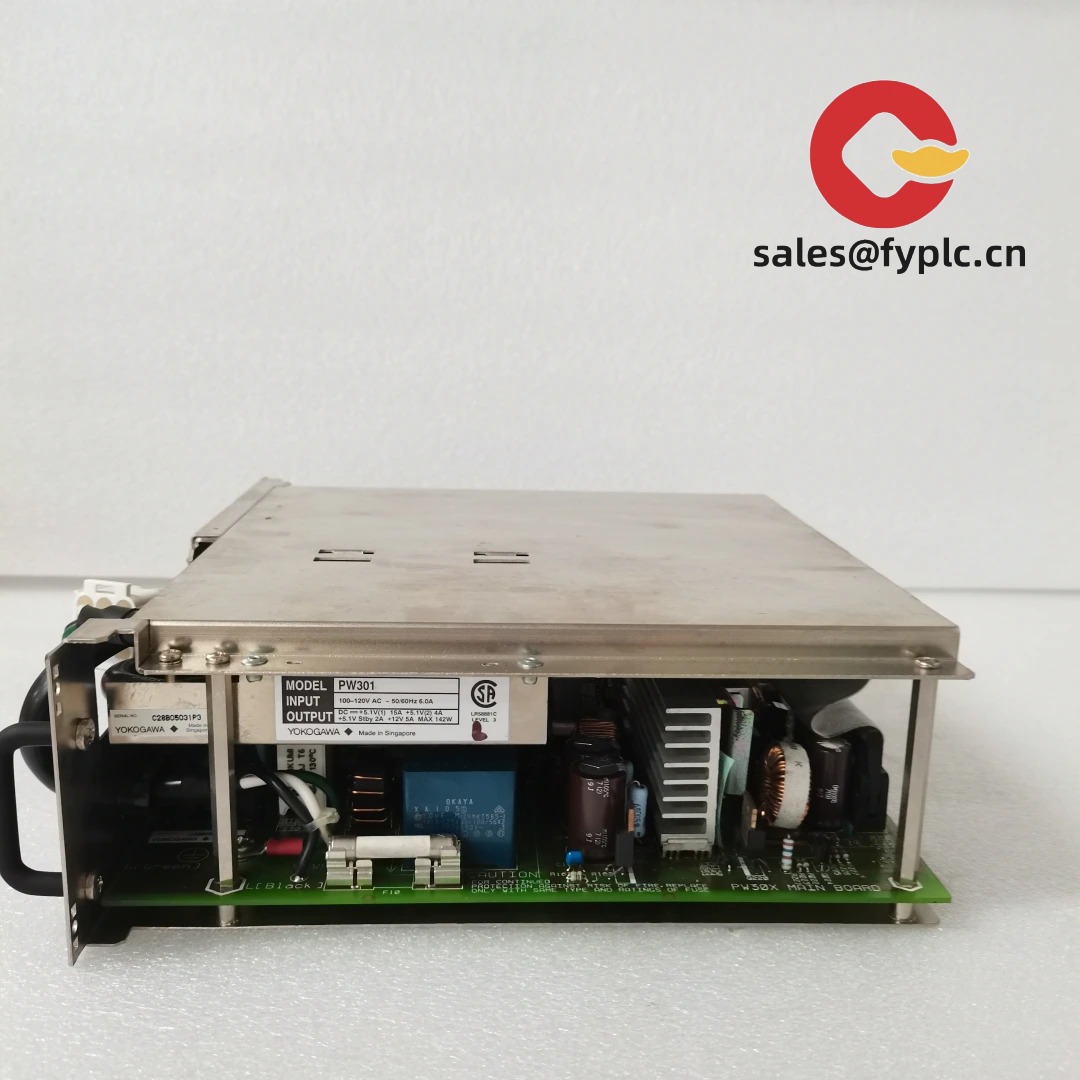

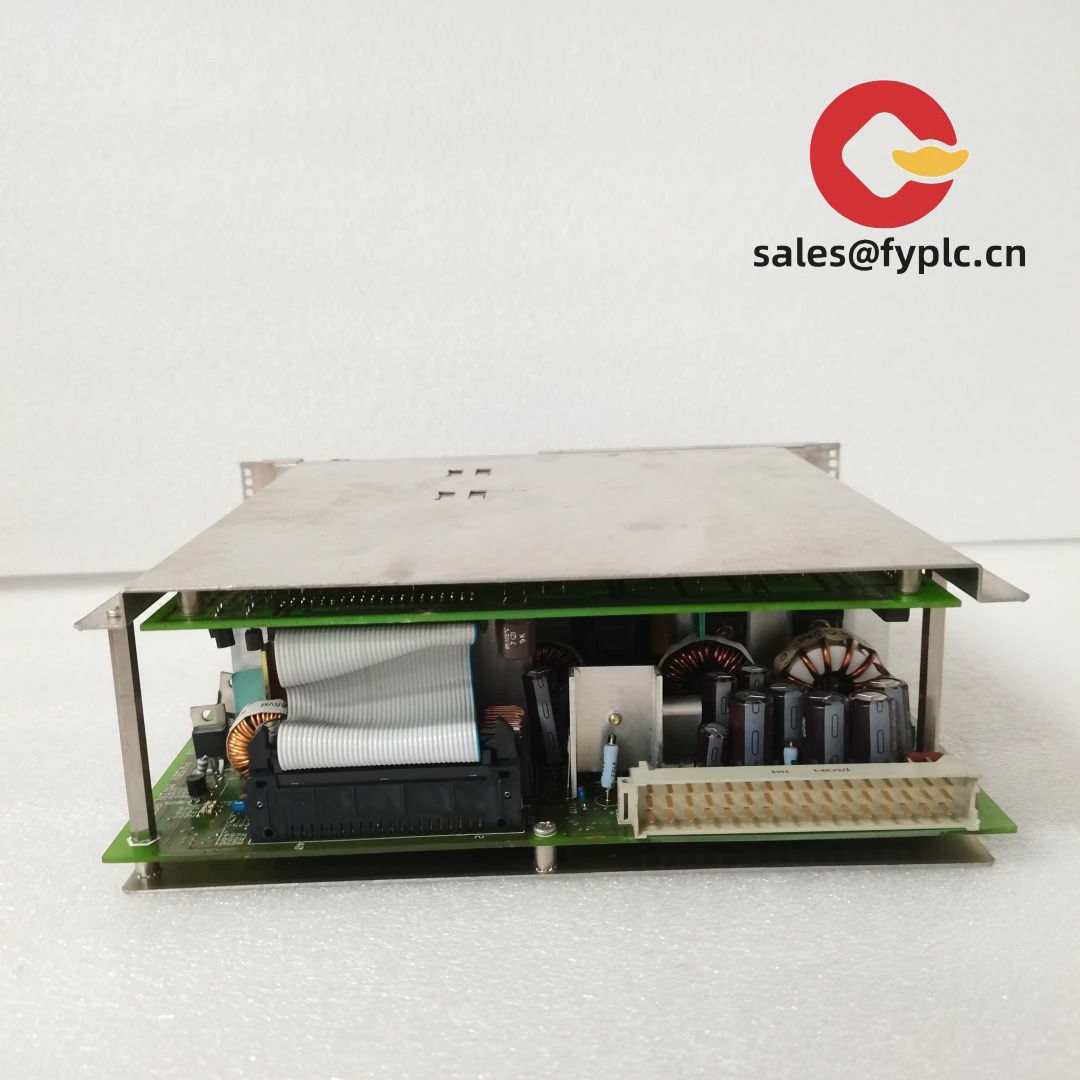

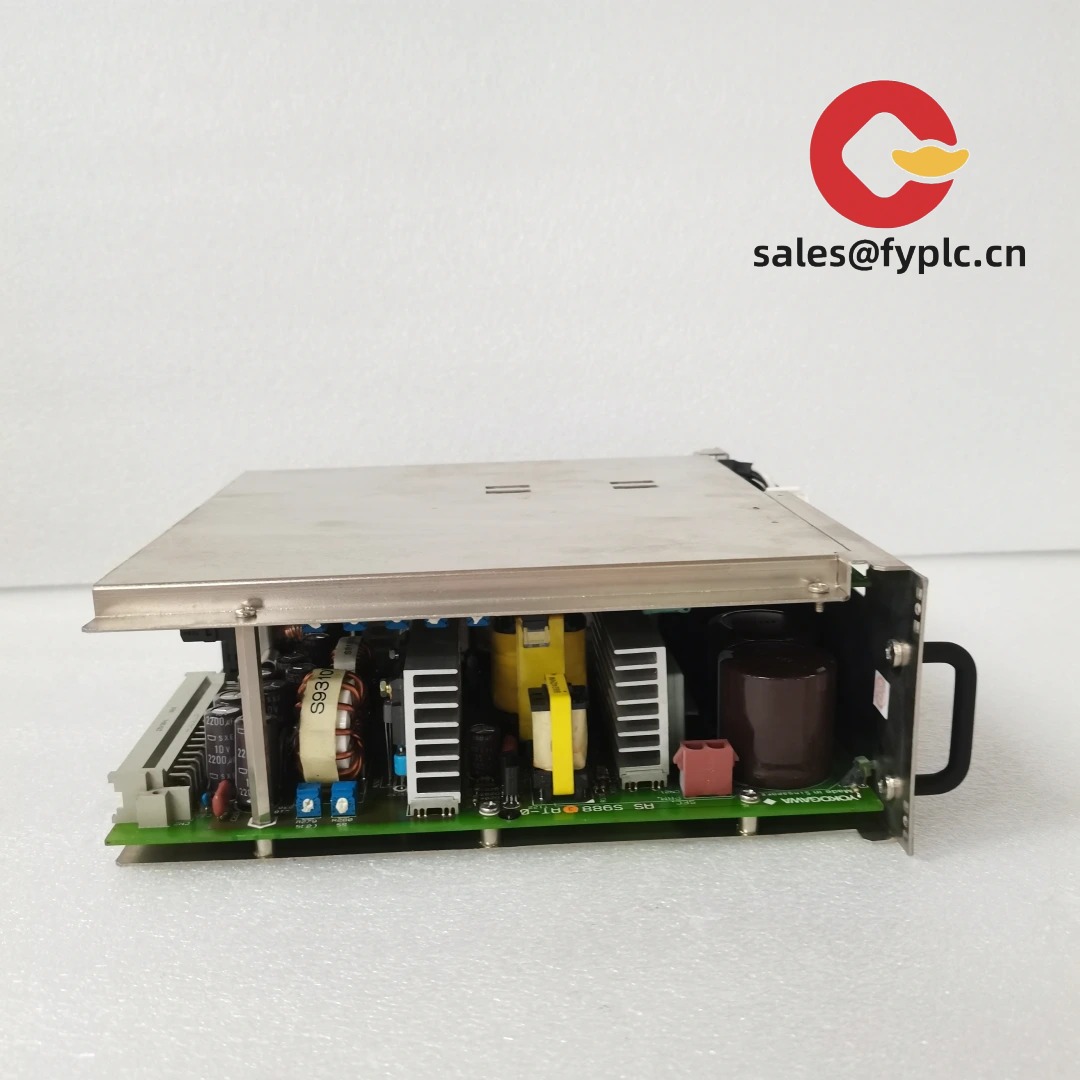

YOKOGAWA PW301 Power Supply Module for Control System Racks

The YOKOGAWA PW301 is a dependable power supply module used to feed stable DC power to Yokogawa control system backplanes. From my experience, it’s chosen as a drop‑in replacement in DCS/PLC cabinets when plants need a quick recovery path with minimal disruption. You might notice that it’s designed for 24/7 industrial duty—solid noise immunity, straightforward status indication, and installation that typically fits neatly into existing Yokogawa system racks.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery time: 1 week for in-stock; no more than one month at the latest

- Payment terms: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Stable DC output to the backplane – Provides regulated power to CPUs and I/O modules for reliable system operation.

- Universal AC input – Typically supports 100–240 VAC, 50/60 Hz, making it suitable for global installations.

- Built-in protection – Overload, over-voltage, and thermal safeguards are commonly included to protect downstream electronics.

- Status indication – Front LEDs (Power/Alarm) help maintenance teams spot issues quickly during rounds.

- Redundancy-ready – On compatible Yokogawa bases, dual supplies can be paired for higher availability.

- Industrial design – Convection-cooled, low ripple/noise output, and robust performance for 24/7 service.

Technical Specifications

| Brand / Model | YOKOGAWA PW301 |

| HS Code | 8504.40 (Static converters—power supplies) |

| Power Requirements | Universal AC input, typically 100–240 VAC, 50/60 Hz |

| DC Output | Regulated DC feed to system backplane; current capacity depends on rack/node specification |

| Operating Temperature | 0 to +50°C (typical for this series) |

| Signal I/O Types | Power output only; no analog/digital I/O |

| Communication Interfaces | None (power module) |

| Installation Method | Backplane/rack-mounted in a control cabinet; supports redundant pairing on compatible bases |

| Status Indicators | Front-panel LEDs (Power, Alarm) |

| Cooling | Natural convection (ensure adequate cabinet ventilation) |

Application Fields

The PW301 is typically used in process automation racks where continuous DC power is critical:

- Petrochemical and refining DCS cabinets (controller and I/O bays)

- Power generation and utilities (boiler/BOP control nodes)

- Water and wastewater plants (pump station control panels)

- Pharmaceutical batch skids and OEM machine control panels using Yokogawa racks

A maintenance supervisor told us they swapped a PW301 during a night shift and had a down I/O node back online in under 15 minutes—no rewiring, just slide, seat, and verify the LEDs. That kind of simplicity tends to save a lot of headache during unplanned stops.

Advantages & Value

- Reliability – Stable backplane power reduces nuisance trips and intermittent module faults.

- Compatibility – Designed for Yokogawa control system racks; typically works as a direct replacement without panel changes.

- Reduced downtime – Clear front indicators and easy access help technicians troubleshoot faster.

- Stocking strategy – A single spare can cover multiple cabinets, which in many cases cuts carrying costs.

- Support – We can assist with selection (single vs. redundant) and cabinet power budgeting if needed.

Installation & Maintenance

- Cabinet & mounting – Install in a clean, dry control cabinet with adequate ventilation. Keep a minimum clearance around vents for convection cooling.

- Wiring – Isolate incoming mains, verify correct grounding, and follow torque specs on terminal screws. Use ferrules for stranded conductors.

- Redundancy – For dual supplies, confirm proper load sharing and alarm wiring on the base unit before energizing.

- Environmental – Operate within the specified temperature range; avoid corrosive atmospheres without appropriate cabinet protection.

- Routine maintenance – Quarterly dust removal (dry air), visual check of LEDs and terminals, confirm no discoloration or odor from overheating.

- Spare policy – Keeping one PW301 on the shelf per control room typically covers most emergency scenarios.

Quality & Certifications

- Compliance: CE and RoHS in most cases; UL/CSA recognition may apply depending on configuration and region.

- Manufacturing quality system: ISO 9001 (manufacturer-level quality system)

- Warranty: 365 days from shipment

If you’d like, send the rack/backplane model or a panel photo and I’ll double-check redundancy support and power budgeting for your exact node. That little step usually prevents sizing surprises during shutdowns.

Reviews

There are no reviews yet.