Description

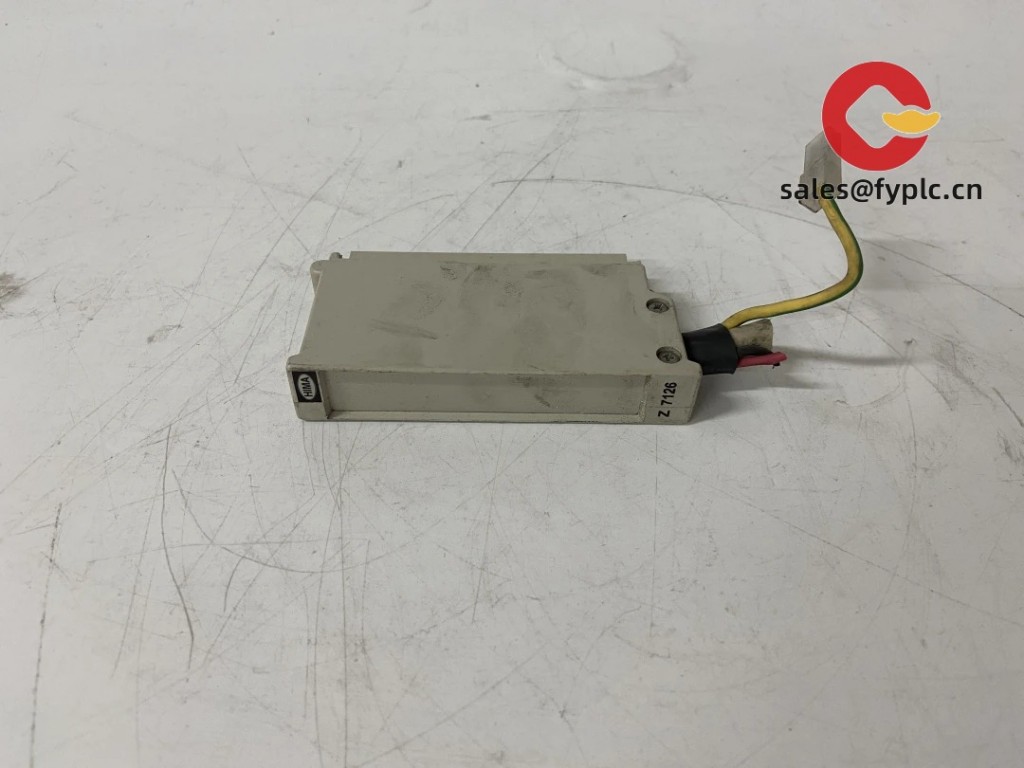

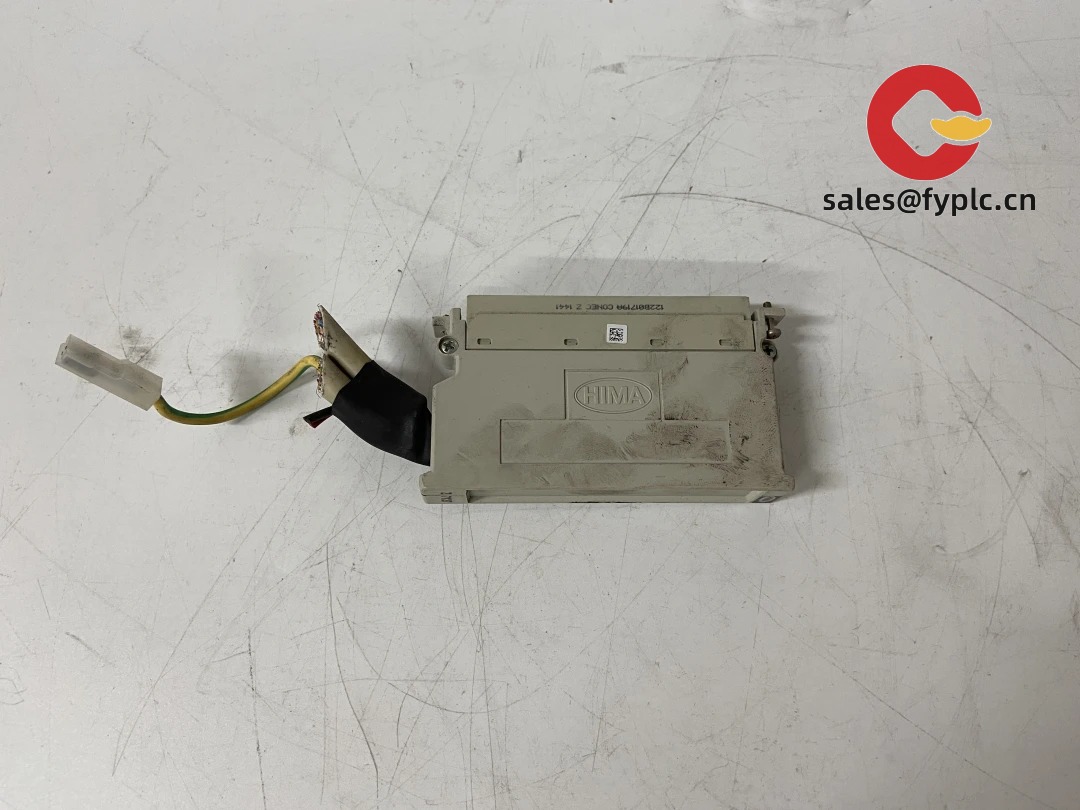

Z2127 Industrial Signal Isolator/Barrier – Reliable 4–20 mA Loop Protection and Galvanic Isolation

From my experience, the Z2127 is typically used as a compact DIN‑rail signal isolator or safety barrier for analog 4–20 mA loops. You might notice that plants deploy it between field transmitters and PLC/DCS analog input cards to break ground loops, reduce noise, and protect upstream electronics. It seems to be a good fit where you need stable measurements in harsh or mixed grounding environments, and in many cases it’s chosen because it’s simple to wire and easy to maintain.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Galvanic isolation (input/output/power): Helps eliminate ground loops and common‑mode noise for cleaner 4–20 mA measurements.

- Loop integrity: Typically supports 2‑wire transmitter loops with minimal burden, keeping accuracy stable over distance.

- Compact DIN‑rail footprint: Narrow housing makes cabinet layouts easier, especially in retrofit panels.

- Noise filtering: Input filtering smooths out spikes from drives and solenoids often found in mixed cabinets.

- HART transparency (typical): Passes HART signals through the analog loop for configuration without removing wiring.

- Clear status indication: Front status LED(s) make it faster to spot loop power or fault conditions.

- Robust terminals: Pluggable screw or spring terminals (varies by revision) for quick swap‑outs during maintenance.

Technical Specifications

| Brand / Model | Z2127 (Industrial Signal Isolator/Barrier) |

| HS Code | 8543.70 (Electrical apparatus with individual functions) |

| Power Requirements | 24 VDC nominal (18–30 VDC), ≤ 1.5 W typical |

| Signal Input/Output Types | Analog 4–20 mA input; 4–20 mA isolated output; HART pass‑through typically supported |

| Communication Interfaces | None (passive analog loop); no fieldbus port |

| Isolation | Input–Output–Power galvanic isolation, typically ≥ 1.5 kVrms |

| Operating Temperature | -20 to +60 °C (typical) |

| Dimensions & Weight | Approx. 12.5–18 mm (W) × 114 mm (H) × 99 mm (D); ~120–150 g |

| Installation Method | 35 mm DIN rail (EN 60715); panel enclosure mounting |

Application Fields

Plants typically deploy the Z2127 wherever analog signals need isolation or hazardous‑area interfacing:

- Oil & Gas / Petrochemical: Isolating pressure, level, and flow transmitters feeding DCS analog inputs.

- Water & Wastewater: Stable readings from remote lift stations and chlorination skids with long cable runs.

- Power Generation: Protecting turbine and balance‑of‑plant instrumentation from noise.

- Food & Beverage / Pharma: Clean integration of sanitary transmitters with validated control systems.

- Factory Automation: Filtering analog signals near VFD cabinets to reduce EMI issues.

Advantages & Value

- Reliability: Galvanic isolation and surge tolerance help keep loops stable when cabinets get electrically noisy.

- Compatibility: Works with most PLC/DCS AI cards expecting a 4–20 mA source; HART typically passes without extra hardware.

- Cabinet efficiency: Slim housing saves rail space; easier to scale channels later.

- Cost control: Reduces downtime from nuisance trips and erratic readings, which usually offsets the unit cost quickly.

- Technical support: We can help map I/O, verify loop power/burden, and suggest spares so commissioning moves faster.

A maintenance lead at a wastewater site told us the swap from a non‑isolated loop to Z2127 cut their nuisance alarms by half during pump starts — not dramatic on paper, but it saved late‑night callouts.

Installation & Maintenance

- Cabinet environment: Mount on 35 mm DIN rail inside a vented panel; keep away from high‑heat sources and VFD output cables.

- Wiring: Use twisted‑pair, shielded cable for analog runs; ground shields at one end to avoid loops. Verify loop burden against transmitter drive capability.

- Power: Provide 24 VDC with adequate headroom; segregate field power and control power where practical.

- Safety: De‑energize the loop before wiring; for hazardous areas, ensure the installed variant and installation match the approved entity parameters.

- Routine checks: Inspect terminal tightness quarterly; clean dust with dry air; confirm LED status; perform loop check/calibration per site SOP.

- Firmware: If your variant includes any configurable electronics, keep its configuration/firmware aligned with site standards.

Quality & Certifications

- Certifications (typical): CE, RoHS; some revisions may carry UL/cUL and, if rated for hazardous areas, ATEX/IECEx markings.

- Warranty: 365 days standard coverage.

If you’re mapping this into a mixed analog cabinet or need confirmation on HART pass‑through and exact burden, share your PLC/DCS card model and loop sketch — we’ll validate the sizing and recommend the safest wiring path for your site.

Reviews

There are no reviews yet.