Description

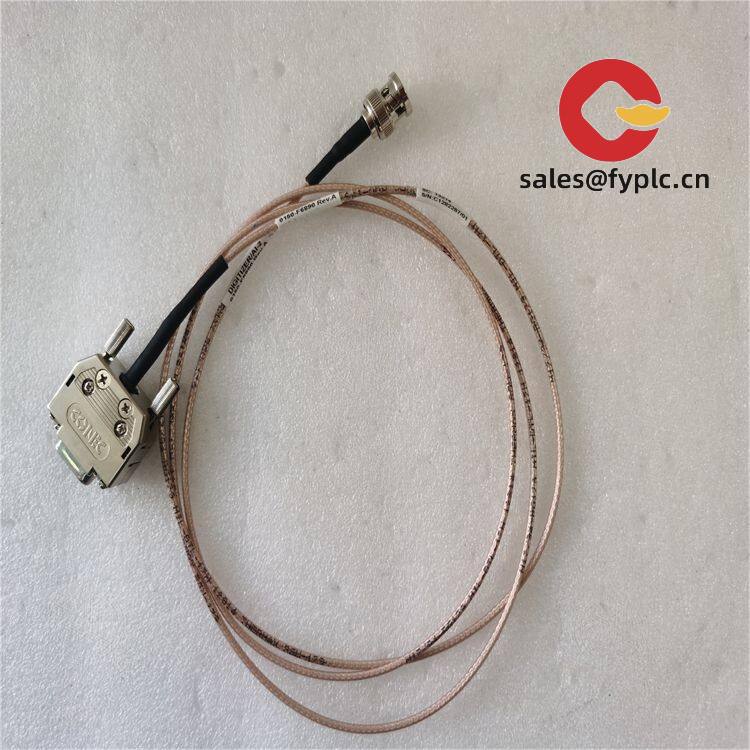

Zygo 1115-801-346 Laser Head Cable – Stable, Low‑Noise Connection for Precision Metrology

The Zygo 1115-801-346 is a factory-terminated laser head cable designed to reliably connect a Zygo laser head to its controller in high‑precision interferometry and displacement metrology systems. From my experience, this part is chosen when customers want a clean, low-noise signal path and a robust build that holds up to daily lab or production use. You might notice that the cable’s shielding and strain-relieved connectors typically reduce drift and intermittent faults that show up with generic substitutes.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Lead time: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment; full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Engineered for Zygo laser heads – Ensures correct pinout and signal integrity between the laser head and controller.

- Low-noise, shielded construction – Helps reduce electrical interference on feedback lines in precision measurements.

- Factory-terminated connectors – Keyed, secure mating to minimize misconnection risk and save installation time.

- Robust jacket and strain relief – Withstands routine handling, routing through cabinets, and repeated service events.

- Service-friendly – Replace the cable without opening instruments; typically restores stability in systems with intermittent signal issues.

Technical Specifications

| Brand / Model | Zygo 1115-801-346 |

| HS Code | 8544.42 (Insulated electrical conductors fitted with connectors) |

| Power Requirements | None (passive cable) |

| Dimensions & Weight | Factory-assembled cable; length supplied per Zygo part specification; low-mass, bench-friendly routing |

| Operating Temperature | Typically 0 to +50 °C (lab/production environment) |

| Signal Input/Output Types | Multi-conductor cable supporting laser head power and feedback/control lines (low-noise analog and control signals) |

| Communication Interfaces | Not applicable (signal pass-through; no protocol interface) |

| Installation Method | Direct connection between Zygo laser head and controller; secure using panel clamps/cable trays; respect minimum bend radius |

Application Fields

This cable is typically used in precision metrology systems where phase stability and signal integrity matter:

- Zygo interferometers in optics labs and calibration rooms

- Semiconductor and flat-panel alignment/metrology stations

- Precision stage feedback and displacement measurement setups

- High-stability measurement benches in R&D and production QA

One maintenance lead at a lithography supplier told us this part “quietly fixed intermittent phase errors” after swapping out an aging cable—seems to be a common outcome when noise or connector wear was the culprit.

Advantages & Value

- Reliability – Factory-terminated and tested, reducing unplanned downtime from loose or miswired connections.

- Measurement stability – Shielding and grounding practices support low noise floors in most setups.

- Compatibility – Correct mating with Zygo laser head and controller ports; avoids pinout guesswork.

- Cost control – Faster swap than instrument repair, often the quickest path to restore spec performance.

- Technical support – Guidance on routing, bend radius, and grounding to get the best stability from your system.

Installation & Maintenance

- Environment – Install in a clean, dry cabinet or lab bench; avoid tight bends, foot traffic, and pinch points. Provide gentle cable trays or saddles.

- Grounding & routing – Keep away from high-current drives, RF sources, and switching power supplies to minimize coupling. Maintain shield continuity.

- Connections – Align keys before mating; fully seat latches or collars. Do not force. Power down equipment during connect/disconnect.

- Bend radius – Use a generous radius (in many cases ≥10× cable OD) to protect internal conductors and shields.

- Routine care – Inspect connectors quarterly; clean with lint‑free swabs and isopropyl alcohol if needed. Check for jacket cuts or crushed sections.

- Spare strategy – Keeping one spare on hand typically shortens troubleshooting time when stability issues arise.

Quality & Certifications

- Compliance: RoHS (typical for instrumentation cabling)

- Manufacturing quality: Produced under ISO 9001‑style quality systems (supplier/manufacturer dependent)

- Safety: Passive cable; follow equipment safety manuals and ESD practices

- Warranty: 12 months from delivery

Note: Compatibility assumes use with corresponding Zygo laser head and controller models. If you’re replacing a field-aged cable, share your system model and current cable label so we can confirm this exact part number is the right fit.

Reviews

There are no reviews yet.