Description

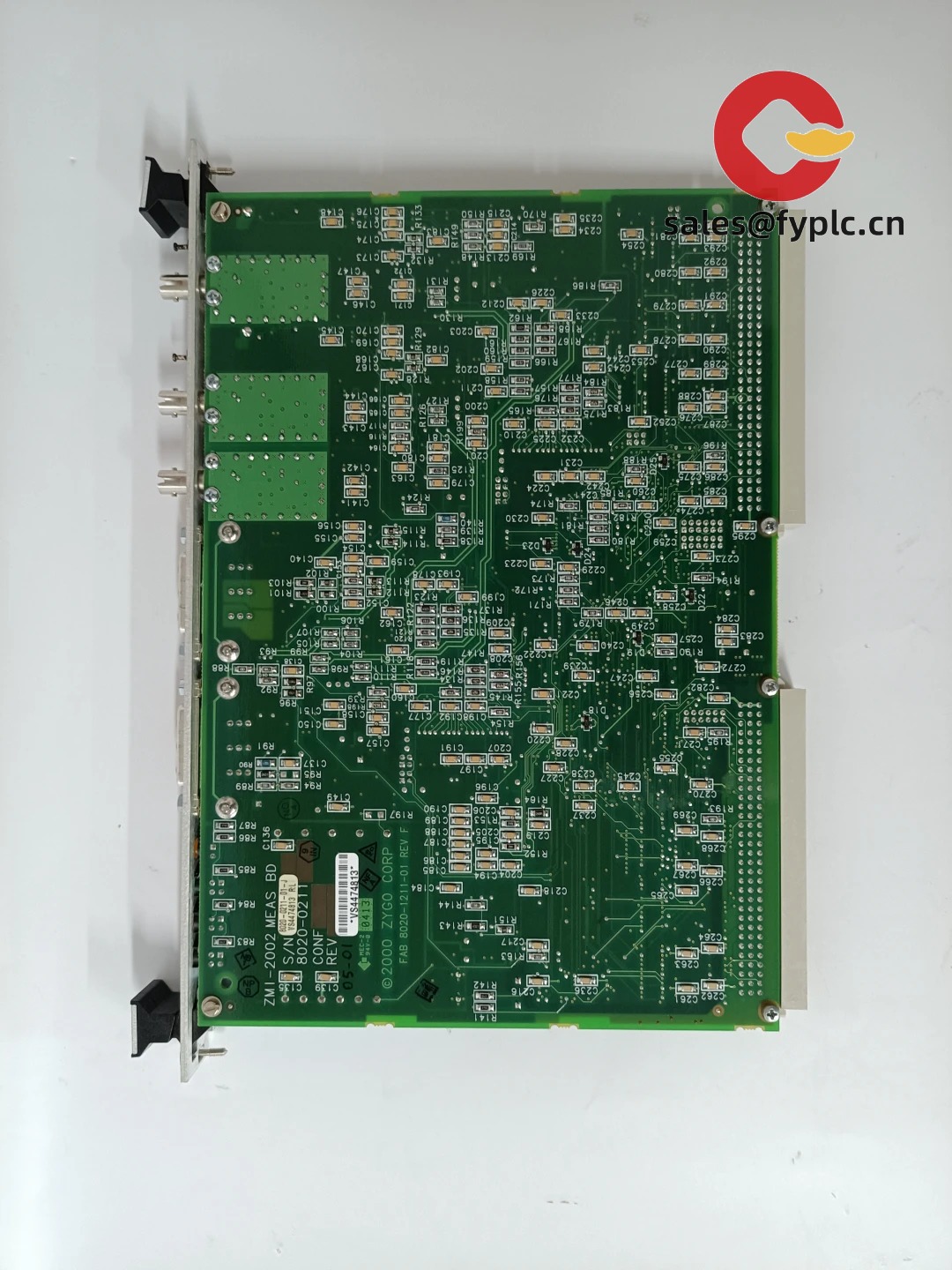

ZYGO ZMI-2002-8020-0211-1-J — Dual‑Axis Laser Interferometer Measurement Module for Precision Motion

The model ZMI‑2002 (part no. 8020‑0211‑1, Rev J) is a ZYGO interferometer electronics module widely used in high‑accuracy motion systems where nanometer‑level position feedback is required. From my experience, it’s the go‑to replacement when a dual‑axis channel is needed for precision stages, metrology fixtures, or for keeping legacy ZMI 2000‑series installations running reliably with minimal requalification.

Company’s Order Placement Process and Guarantees

- Warranty: 365 days

- Delivery: 1 week if in stock; no more than one month at the latest

- Payment: 50% advance payment, full payment before delivery

- Express options: FedEx, UPS, DHL

Key Features

- Dual‑axis interferometer processing – Typically handles two measurement channels for X/Y or X/θ applications, keeping controller integration straightforward.

- Nanometer‑class resolution – Designed for high‑precision motion feedback; users usually see stable, low‑noise counts in controlled environments.

- Quadrature outputs for motion controllers – Differential RS‑422 A/B/Z signals in many cases, so existing servo controllers read it like a high‑resolution encoder.

- Drop‑in for ZMI 2000‑series racks – Slides into the ZMI chassis; no external PSU or custom brackets in typical setups.

- Stable metrology performance – Built for long‑term drift stability, which helps during extended litho, inspection, or alignment runs.

- Proven in semiconductor and precision optics – Commonly used where positional repeatability and traceability really matter.

Technical Specifications

| Brand / Model | ZYGO ZMI‑2002 (8020‑0211‑1, Rev J) |

| HS Code | 9031.49.00 (Other optical measuring/checking instruments) |

| Power Requirements | Powered by ZYGO ZMI 2000‑series chassis; no external power supply required |

| Dimensions & Weight | Single‑slot plug‑in module for ZMI chassis (rack module form factor) |

| Operating Temperature | 15–30 °C recommended in controlled laboratory or cleanroom environments |

| Signal Input/Output Types | Dual interferometer measurement inputs; differential RS‑422 A/B/Z quadrature outputs; status/marker lines |

| Communication Interfaces | Serial service interface (RS‑232) commonly available for setup/diagnostics |

| Installation Method | Slides into ZMI 2000‑series chassis slot; front‑panel connectors for signals |

Application Fields

You might notice that this module shows up wherever high‑end positioning is the bottleneck. Typical uses include:

- Semiconductor lithography and wafer inspection stages

- Precision optics alignment, interferometric testing benches

- Coordinate measuring machines and ultra‑precision machine tools

- Laser micromachining, MEMS motion systems, and research labs

- Retrofits where encoder‑like outputs from a laser interferometer are preferred

Advantages & Value

- Reduced integration risk – Keeps existing ZMI racks and controller interfaces intact; typically no rework on motion IO.

- High stability – Consistent counts over long runs help maintain tool overlay and repeatability.

- Serviceability – Easy module swap minimizes downtime; many teams keep a spare to cut recovery time to minutes.

- Lifecycle support – Useful for sustaining legacy ZMI platforms that are still validated in production flows.

- Cost control – Extends the life of installed interferometer heads, cabling, and motion controllers.

A precision optics customer told us they “dropped it into a ZMI rack and were back collecting nanometer‑stable data before lunch,” which—while not glamorous—saves a shift of lost metrology time.

Installation & Maintenance

- Cabinet & environment – Install in a ZMI 2000‑series chassis within a clean, temperature‑controlled area (typically 15–30 °C). Ensure front‑panel airflow isn’t obstructed.

- Wiring – Use the specified shielded cables; keep interferometer and quadrature lines separate from high‑power motor wiring to reduce noise coupling.

- ESD & handling – Observe ESD precautions when inserting/removing the module; seat firmly until the latches engage.

- Calibration – Verify scale factors and reference offsets after installation or when environmental conditions change.

- Routine checks – Periodically inspect connectors for contamination; clean with appropriate optics‑safe methods if fiber or optical connections are present.

- Firmware/parameters – Where applicable, back up configuration and update firmware only under controlled change procedures.

Quality & Certifications

- CE and RoHS compliant in typical configurations

- Manufactured under ISO 9001 quality systems

- Warranty: 12 months (365 days) from delivery

Ordering Notes

For model ZMI‑2002‑8020‑0211‑1‑J, please confirm rack compatibility, channel count, and the required output format (e.g., differential quadrature to the motion controller). If you’re replacing an existing board, sharing the current part/revision helps us ship a form‑fit‑function match faster.

Reviews

There are no reviews yet.